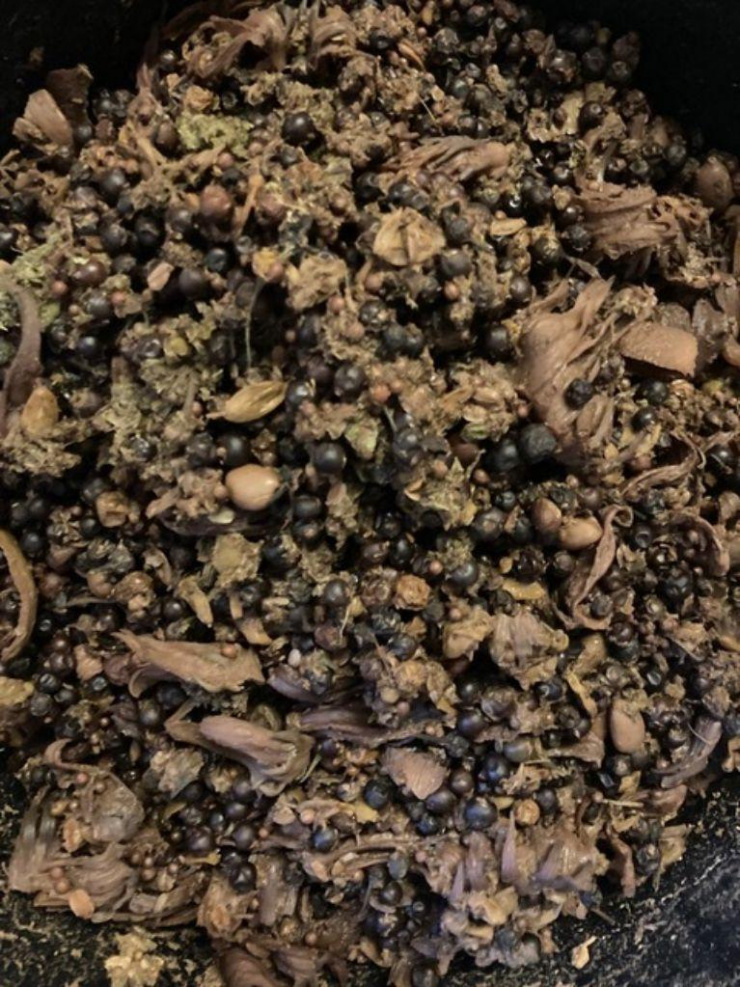

What happens to spent botanicals

After distillation we are left with a mixture of used botanicals in the bottom of the still. We used to put them in our hot bin composter but these days we have a lot more to deal with and our hot bin struggled to keep up with them. So now we scoop them out and put them in our Andigestion bin.

The bin is collected and taken to Andigestion’s Holsworthy Biogas Plant. The plant processes industrial and domestic food waste to create renewable energy and a nutrient rich fertiliser. Andigestion were the first UK operator to run a food waste only AD plant and are hugely experienced in organic waste treatment.

For those of you who enjoy the details, this is how they do it:

The start of the process: After the waste has been delivered to site it enters the process in a variety of ways. Packaged waste is fed into a machine that separates the packaging from the food. The packaging is then recycled, if possible and the food is mixed together with other waste streams in a tank.

Receiving the feedstock: The waste is then mixed together in a mixing tank to turn it into a pumpable 'soup'. This process also helps to homogenise the waste.

Preparing the feedstock: This important part of the process allows them to accept animal by-products such as fish and abattoir waste. The macerator ensures any that food particles in the ‘soup’ are reduced to below 12mm ensuring that it can be fully heated in the next stage of the process.

Killing unwanted bacteria: The food waste is heated to 70°C for one hour ensuring all pathogens are killed. This process also helps them to heat the feedstock so that the digesters are at the right temperature, 38°C – 40°C, to produce the biogas.

Production of biogas: Following pasteurisation, the food waste is pumped into large tanks called digesters. The digesters contain cultures of anaerobic bacteria that digest the waste over a period of approximately 55 days. The digestion process results in the production of biogas which is around 60% methane and 40% carbon dioxide.

Storing bio-fertiliser: After 55 days the digested material is pumped into a storage tank ready to be used as a liquid fertiliser. The bio-fertiliser is passed through a screening machine that removes any residual inorganic material such as plastic or grit which can’t be digested. The biofertilliser is totally free from pathogens and contains high quantities of nitrogen, potassium and phosphate; all vital nutrients for plant growth.

Energy production & storing renewable energy: The biogas that is produced through the anaerobic digestion process is on site. The storage system allows them to use the gas when required meaning they can produce power when people need it. This is a huge advantage over other renewable systems that can’t efficiently store energy and can only produce power when the elements allow.

Energy production: The energy stored in the biogas is converted into electricity and heat or biomethane. Some of the electricity produced is used to power the plant but most of it is exported to the National Grid. The heat is used to run the process such as pasteurisation and to heat on site water. Biomethane is injected to the local medium pressure grid, and used by local consumers in place of natural gas.

Bio-fertiliser & spreading the bio-fertiliser: The bio-fertiliser is spread to land as a replacement for mineral fertilisers. Its use ensures that vital nutrients in the food waste are recycled and returned to the ground.

For more information, check out their website https://www.andigestion.co.uk